Crafting Safety: An Organic Cannabis Farm’s Quest for Cannabis Contaminant Control

An Organic Farm’s Quest to Preserve Craft-Quality Cannabis, Prevent Aspergillus, and Prepare to Neutralize Other Pathogens.

By Vincent Deschamps and Jamie Toth

Executive Summary/Synopsis:

54 Green Acres is an organic farm Southern Oregon that is certified by Sun & Earth™ and Certified Kind™. Both certifications represent the gold standard in organic cannabis certifications. Oregon proposed regulations for cannabis testing for pathogens, specifically Aspergillus. Both indoor and outdoor farms within the state experienced a failure falling around 40%. 54 Green Acres set out to explore both remediation as a form of redemption for positive tests, and prevention as an alternative. Because the farm is certified organic, and because 54 Green Acres cares deeply about the quality and integrity of what gets to the consumer, remediation via the use of ozone and radiation were discounted as possibilities. While other commercial producers use these remediation methods, 54 Green Acres decided to go all in on pathogen prevention in a move that literally ‘bet the farm’ on prevention.

Their approach used technology that would improve indoor air quality while drying and curing, in addition to a complete makeover of the indoor facility used for drying and curing. The plan was to turn the facility into an ultra-sanitary ‘clean room’ and to use of an air filtration / treatment product that would provide clean air and surfaces. In order to perform product selection, key personnel from 54 Green Acres talked with growers in other states that require testing for Aspergillus.

While 54 Green Acres Farm was exploring their options, a lawsuit brought by Oregon farmers ultimately brought Aspergillus testing within the state to a halt, but 54 Green Acres decided to continue forward with their project.

Introduction

Since 2015, 54 Green Acres has been an award-winning Southern Oregon farm producing quality craft cannabis with the highest combination of terpenes and cannabinoids. While many understand the function of cannabinoids in cannabis, it’s the terpenes that produce the smell, aroma, and taste. The exceptional terpene profiles produced by 54 Green Acres are derived from proprietary genetics that thrive in their organic terroir. 54 Green Acres farm uses all means permitted by their organic certifications to produce cannabis with amazing aromas and high, award-winning quality. Their biodiverse garden is both Certified Kind™ , and Sun & Earth Certified ™. Their water is crystal-clear, and comes from Sucker Creek, which is used to irrigate 15 acres of the farm. Water rights to Sucker Creek were granted in 1882.

In March 2023, the Oregon OLCC created and instituted several microbiological tests for adult-use cannabis. One of these was a non-detect test (pass / fail) for four species of Aspergillus known to be pathogenic in humans. Aspergillus is a fungus that can be found everywhere. Cannabis grown outdoors and tested prior to the new regulations was exempt. However, some farms began to test their already approved offerings for aspergillus. If those tests failed, the OLCC had their products removed from stores via recall.

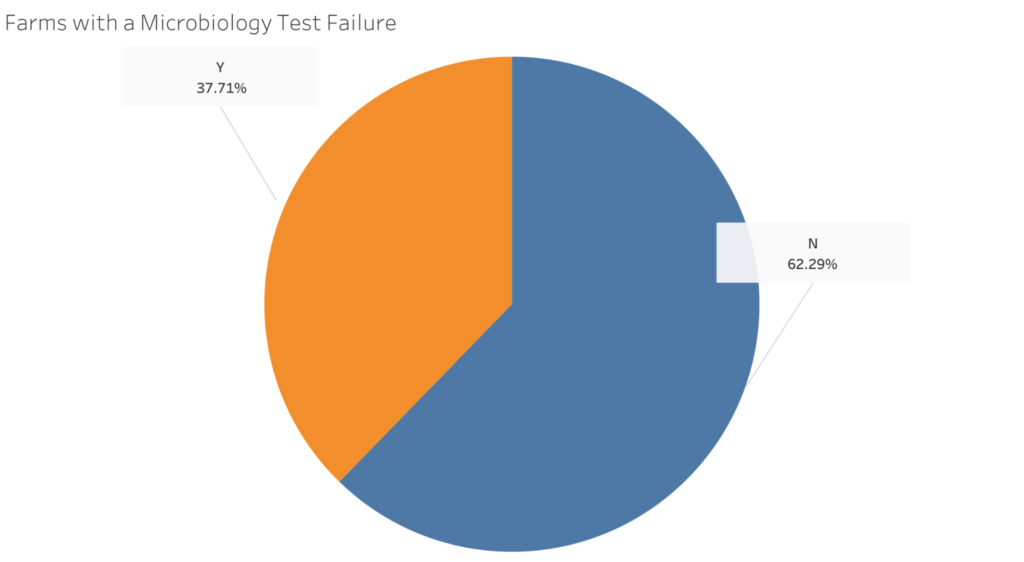

Rumors began to circulate regarding the failure rates of farms that submitted their cannabis for testing. Public information requests from the state yielded information that 37% of farms that submitted products for testing had a failure among one of their batches.

As failure meant a batch of cannabis could no longer go to market, or worse – be recalled from dispensary shelves – it was important that each producer create a microbiological strategy, especially for the four species of Aspergillus. Methods to mitigate risks were to introduce a kill-step to the flower post-cure using ozone or radiation or to completely overhaul facilities and handling processes, especially post-harvest.

In August of 2023 the OLCC temporarily suspended the Aspergillus testing based on a lawsuit by growers in Oregon. 54 Green Acres had already started down the path of process reinvention and microbial prevention and continued their efforts. They based their actions on the belief that testing for pathogens would expand in Oregon, even if not for this particular one. As discussions about federal rescheduling and descheduling of cannabis continue to occur, it is likely that interstate cannabis trade would require Aspergillus testing, as many states with legalized cannabis also have non-detect testing for Aspergillus. 54 Green Acres has a long-term view on cannabis Federal legalization and believes that to be able to ship to those other states with aspergillus testing requirements, it would necessitate passing non-detect tests for Aspergillus regardless of whether Oregon itself requires it.

The kill-step or ‘redemption’ methods that are available in the industry that involve ozone and radiation treatment of cannabis post-harvest are not compliant with Certified Kind ™ or Sun and Earth ™ certification, nor were they compatible with 54 Green Acres Farm’s overall philosophy of cannabis cultivation. Instead, the farm sought to prevent Aspergillus. This required extensive evaluation of processes used in the garden, drying, and curing of their cannabis. It also required extensive redesign of portions of the facility.

The information contained in this report demonstrates the extent of the redesign, including insights and lessons learned in adopting the changes to the garden, indoor facility, and the air in that facility. This case study does not aim to be a controlled scientific experiment, as there wasn’t enough time or resources to support such a study. Such a study would require the maintenance of two gardens, two indoor facilities, and two separate processes for them, in order to cover all possible options to test the hypothesis.

The intent of this white paper is to cover the experience of the farm and document its processes and lessons learned in the hopes it will provide other cultivators with useful information on how to control and neutralize Aspergillus and other pathogens. Many pathogens are found naturally in the air, water, soil (or other growth mediums), and it is important for business owners in the industry to understand the experiences of others when facing similar decisions.

After introducing these changes, this approach created other benefits for the 54 Green Acres team and their customers. That information is also included in this white paper.

The Quest

Vin Deschamps, owner of 54 Green Acres, felt it wasn’t the soil that was the issue. “We knew that people who were growing with natural soil indoors were failing, and they concluded it was the natural soil that was the problem. But we knew we were organic and keeping everything super clean. We felt like it wasn’t the soil that was the issue.” The 54 Green Acres team decided that in order to meet the non-detect requirements, three areas would need focus: the Garden, the indoor facility, and the facility’s air quality.

The Garden

At 54 Green Acres is committed to providing customers with clean, organic products. Because of the federal status of cannabis, federal organic certification of cannabis is not yet possible, thus farms interested in the designation have to seek other certification methods for their organic inputs and processes. 54 Green Acres holds two of the gold-standard certifications for organically grown cannabis, Certified Kind™ and Sun + Earth™. The guidelines of these certifications only allow the use of OMRI (organic) certified amendments, certified pest management products, and certified pathogen controls. These certifications do not allow the usage of any non-organic pesticides or post-process treatments.

Indoor Facility

The objective of redoing the indoor facility was to pass compliance testing for Aspergillus. While the State of Oregon temporarily suspended the testing for Aspergillus in August as a requirement, Aspergillus as just one of many pathogens that will need to be neutralized as a cannabis producer in order to ship products to other states with Aspergillus testing requirements, when it is finally legal to do so. To the best of our understanding, this is the first fully documented testing for Aspergillus for cannabis grown outdoors and then dried and cured indoors.

Prior to renovation, the indoor facility had gravel floors as it was situated in a rustic barn.

Air Quality

As Aspergillus and other pathogens feed on dead plant matter, the importance of air quality within the drying and curing space was vital. The barn used to contain the indoor facility allowed a lot of air to be free flowing, including a cupola at the top. Any place where air could be exchanged with the air outside presented opportunities for Aspergillus to be introduced to the cannabis crop during the drying and curing process.

Main Products and Services Used

Canna Klean – Environmental Consultants

54 Green Acres engaged Matt Iarussi of CannaKlean (CannaKlean.com) to provide guidance to 54 Green Acres and its contractors on how best to renovate the existing facility, and create an environment that is as close to a clean room as was feasible. With over 45 years of experience, CannaKlean is a company that has been in the business of environmental contaminant prevention for years. They carry over 30 certifications for their work in contamination mapping in grows, environmental remediation, deep cleaning and emergency response, and process and procedure re-engineering.

Matt Iarussi, the COO of Canna Klean, has been growing cannabis for over 20 years and uses his insights to help clients to address Aspergillus and other pathogens and contaminants in their own grows. He understands the challenges that growers face in states where non-detect tests for Aspergillus are part of the regulatory structure. “There are a lot of ways you can spend your CapEx to address these sorts of issues, but the long-term business smarts are focusing on making a good, clean grow that is non-conducive to mold/microbial growth” Matt’s work with 54 Green Acres included reviewing equipment for air movement such as fans, and evaluation of larger purchases.

Omni Clean Air – AgriAir 1000, Agricultural Surface and Air Cleaning / Purifying System

AgriAir 1000 (AA1000) Surface and Air Cleaners from Omni CleanAir were installed to treat the indoor air. The AA1000 unit employs photo hydro ionization (PHI) technology, which generates Hydrogen Peroxide Plasma that seeks out and removes 99.99% of mold, viruses, and other bio-contaminants. The process is natural and safe, where the H2O2 reverts to Oxygen and Hydrogen once they have come into contact with a contaminant. Unlike some similar technologies in use, PHI does not generate ozone.

Omni CleanAir has been in business for over 30 years with the mission to eliminate the illnesses caused by unhealthy air. The majority of their products are HEPA filtration-based industrial air scrubbers and air purifiers. Often the same machine can be configured as a negative air machine. Their machines haven’t just been used for agriculture – they provide clean air for high stakes applications including asbestos abatement, containing pathogens in patient isolation spaces, and capturing dangerous particles such as silica dust generated during manufacturing processes. Similarly, the portfolio has been used for over 30 years to provide clean air solutions for protecting high value agriculture crops from the dangers of molds, mildews, cross-pollination, etc.

While Omni CleanAir’s clients are diverse, they are still sensitive to the needs of the cannabis growers they work with. Jeff Abramson, Vice President of Product for Omni CleanAir said, “The photo hydro ionization technology is super effective at neutralizing these pathogens like mold or aspergillus and doesn’t create ozone. It’s all organic, all the work an organic grower puts into their certifications, the last thing they want to do is introduce something like ozone. The primary market for the AA1000 is agriculture.“

The AgriAir 1000 product was selected based on many factors, but the largest differentiator for the 54 Green Acres team was Omni CleanAir’s willingness to allow them to speak with their clients. The team was put in touch with Brandon Schmitzer of High Mountain Cannabis Company. Brandon is the Chief Operations Officer and Head Grower.

High Mountain Cannabis Company has a 9700 square foot facility in Vassar, MI. The facility itself can cultivate up to 3,500 plants. High Mountain faced a situation more dire than the one 54 Green Acres did – they had failed a test for Aspergillus. High Mountain seeks to grow “the genetics the best they can be grown, we want them to be the best in the class.” After the test, they had their lab come out and test their air, and found out that there was Aspergillus in the air of their facility. This meant they had a bigger problem than just one crop.

Brandon began an extensive research project on how to convert the facility and clean it of any pathogens, and to prevent as many of them from coming in as possible. Brandon’s research took him right down to the grow medium used, and High Mountain Cannabis Company underwent a series of sweeping changes in 2021 to ensure that pathogens would no longer be a problem. Brandon wanted to bring their facility as close to a clean room environment as possible, and he designed a multi-pronged solution that included UV-C lights, entrance protocols, and many other tactics – and he ultimately chose Omni CleanAir’s AgriAir products to neutralize pathogens in the air. “With all of this in place we’ve never failed an aspergillus test again. All of our Total Yeast and Mold standards are below the threshold for medical use, and that’s without any sort of remediation process.”

Brandon’s ambassadorship for the Omni CleanAir, and his ability to walk the 54 Green Acres team through High Mountain’s experience and lessons learned made the difference when it came to selecting the air filtration system for their indoor facility.

Antimicrobial & Waterproof paint – Benjamin Moore

Other Materials – Home Depot

Plywood, Building Materials, FRP Board

The Changes

Interior Makeover

The 54 Green Acres team completely re-did the interior of the indoor facility. Under the guidance of Matt Iarussi, the rustic barn was first stripped down to the studs.

All of the bare wood was coated with an antimicrobial paint. The picture below shows the barn before the insulation and walls went up. All of the structural bare wood was coated.

Once this work was complete, it was insulated, and then plywood was used as a base. FRP board was glued to the plywood.

A new concrete floor was poured and coated with epoxy.

All ceilings were painted with waterproof paint and new waterproof lighting was installed.

The building has a cupola and a large fan, both areas were retrofitted with the ability to open or close them completely and then equipped with HEPA filters. Joshua Kent, Director of Operations at 54 Green Acres did extensive research to find a place that would make custom-sized HEPA filters for the cupola, which was difficult due to the size.

Equipment was added to measure temperature, humidity, and IONs real-time. The existing three dehumidifiers and dual heaters were retained.

This overall renovation project took 90 days to complete, but there was still work to be done.

Air Quality

Once interior renovations were complete, the new AgriAir 1000 units were installed.

Processes and Procedures

With all of the interior renovations complete, there was still work to be done. 54 Green Acres leadership would need to create processes and procedures to maintain the facility’s cleanliness, move product between indoor and outdoor spaces without introducing contamination. The changes implemented impacted nearly every part of operations.

In the garden, the team made sure they were using sanitized shears. Sometimes bin liners had to be used in totes. It was hard to make sensible changes that wouldn’t impede their ability to harvest while also maintaining very high standards of cleanliness, but Josh found that everyone was receptive and willing to make the changes necessary.

The indoor space is where most of the changes took place, and there was an overall increase in labor, as daily cleaning sessions, weekly deep cleans, and laundry were added to the already busy schedule for the 5-person crew. Cleaning sessions addressed the space from the ceiling to the floor, and were key to the farm’s approach. It took creative problem solving to figure out how to move between the garden and the indoor facility without introducing contaminants, while still being sensible about operational needs.

In addition to all of this, the team had to learn an entirely new mindset in cannabis cultivation.“You have to do things with a preventative mind instead of a reactive mind,” Joshua Kent explained. “When you do them preventatively you think of doing big things in little increments, and not ‘going gangbusters.’ Instead, every little action leads to being preventive.”

Real-time monitoring and testing

54 Green Acres farm added the capability to monitor and measure temperature, humidity, and ions in real-time. This allows them to maintain the desired temperature and humidity levels during both drying and curing. This was a significant improvement over their capabilities prior to having the room redone. They monitor the ions emitted from the AgriAir 1000 present in the room so that they can ensure the equipment is operating properly.

Findings and Lab Results:

The Oregon Liquor and Cannabis Commission (OLCC) defines the testing requirements for recreational and medical cannabis. Terpene testing is not a requirement but 54 Green Acres has been testing for Terpenes since 2015 to ensure the smell, aroma, and taste of their cannabis offerings maintain consistent quality. 54 Green Acres prides themselves on their terpene profiles, and was the winner of the Oregon GOAT cup, a science-based contest measuring the combination of THC and terpenes. Ensuring that nothing they did in the remodel would negatively affect either terpenes or cannabinoids was paramount.

As of December 31, 2023, the farm has passed all of the 2023 compliance tests that meet the OLCC requirements in Oregon. In addition to those tests, the farm measured ION levels in addition to temperature and humidity real-time, and have documented those data.

In addition to the standard compliance tests, 54 Green Acres requested that the proposed microbial tests, in addition to the non-detect test for Aspergillus, be run. Out of 39 tests, the farm passed 37, which represents a 95% success rate. 54 Green Acres had 13 different cannabis strains tested at 3 different times:

Wet, at harvest after being cut down and before entering the drying facility

Dry, after being inside the drying facility for 5 to 7 days.

Cured, after undergoing out curing processes for 5 to 7 days.

The two tests that failed were tests performed after the curing process for two strains that were cured at the same time. 54 Green Acres and their testing lab, ChemHistory, are investigating what may have caused those failures .

Other Findings & Benefits

A Challenging Grow Season Didn’t Impact the Positive Changes. The harvest weather was the worst in 9 years of growing. Southern Oregon experienced a bomb-cyclone weather event and the heavy rain and cold impacted the grow cycle. Still, all compliance tests passed, the THC amounts were high (between 22 and 30%), and terpene levels were consistent with prior years. All of the 54 Green Acres test data is on their website at 54GreenAcres.com both THC and terpenes dating back to 2015.

Air Quality Impacted Employee Health. The quality of the air inside the indoor facility was noticeably improved. The air inside the building was clean and refreshing for the harvest crew. While the AA 1000 machines were installed to remove aspergillus and other bio-contaminants, it had the added side benefit of also removing pathogens, and the employees stayed healthy and enjoyed cleaner air in general. Josh noted, “It’s the first time that no one had a nasty bug like the cold or the flu where they had to wear a mask and take work off. It was nice to have a healthy crew.”

Looking Ahead. The farm’s next crop, cloned from 2023 plants, have already started to thrive. 54 Green Acres recently brought the clones (mother plants) taken from the plants in early August 2023 and raised in the clone shed (limited space) into the renovated indoor facility. They were undersized when they entered the facility, but within a week they grew 6 inches and looked super healthy.

Impact on THC and Terpenes. 54 Green Acres planned and anticipated there would be little to no impact to the terpene and cannabinoid profiles from using the AgriAir machines. The test results were all consistent with past terpene and cannabinoid test percentage results. THC, in particular, was actually higher for most of the genetic strains but that could have been the result of multiple factors such as: using more beneficial microbes, Yucca and other organic (OMRI certified) amendments, reduced pest pressure, a clean and stable facility, in addition to the enhanced air quality with the AgriAir machine use.

Enhanced Smell. A dramatic reduction of the cannabis smell in the facility as a result of the filters in the AgriAir units was expected. However, one of the staff approached Vin Deschamps and said, “Vin smell this Green Dragon that was just cured, it smells amazing”. Vin responded they should go outside and smell it, at which point the staff member was blown away with the aroma which he described as 100 times stronger than inside the facility. Farm leadership knew the equipment would impact the smell and had been hoping for little to no smell inside the facility, yet weren’t expecting the strong aroma of their cannabis terpenes when taking cannabis out of the facility.

Reduction of Allergies for the Crew. The other benefit was that some of the harvest crew who had been with us in prior years commented that they had allergies and had always worn a mask indoors. This year they were able to go maskless for nearly two months working indoors. This may be due to fewer particles floating in the air positively impacting their allergies.

Discussion:

As a craft farmer producing 600 to 1,000 pounds of flower, 400 pounds of trim, and 2,000 pounds of fresh frozen flower and processing material annually, spending upwards of $60,000.00 on a facility remodel was a “bet the farm experience” for 54 Green Acres. 80% of the costs were construction costs. While it may have been possible to just add the AgriAir equipment to their environment, they still wanted to avoid any post-harvest redemption services. They went all in on the remodel. The benefits don’t just stop at the farm’s ability to pass microbiological tests, but also include a new ability to control temperature and humidity year-round, maintain a healthier set of mother plants that are used for cloning, and increase clones’ health prior to planting. The benefits to the staff and their health were also a big plus for the farm.

Conclusion:

54 Green Acres is satisfied, having accomplished what they set out to accomplish, in addition to knowing that what they did to improve the facility has brought many benefits.

While they knew that the AgriAir 1000 Machines would likely remove significant amounts of Aspergillus, they felt a much more comprehensive change would not only increase the likelihood of this, but also provide many other benefits such as temperature and humidity control, and overall cleaner air for the staff.

References/Contacts:

Vincent Deschamps is the owner of 54 Green Acres farm. The mission and values of 54 Green Acres is, simply, Purely Organic, Amazing Results. Vin is dedicated to creating the finest craft cannabis using organic methods. He has also participated in Compassionate Care Programs at local dispensaries, donating cannabis that can be bought by veterans in need for steep discounts. Vin can be contacted via email at: Vincent.deschamps@54greenacres.com .

Matt Iarussi is the Chief Operating Officer of CannaKlean (Cannaklean.com). Matt and his team provide prevention and redemption consulting and services to both craft and large companies in the cannabis industry. Matt and his team reviewed the objectives and guided 54 Green Acres in every phase of construction to develop their clean facilities, including equipment evaluation. Matt can be contacted via email at: matti@cannaklean.com .

Omni CleanAir is a center of excellence in the realm of indoor air quality management. Recognized for its unwavering commitment to safeguarding the health of people and plants in diverse environments, this pioneering company employs cutting-edge technologies and innovative solutions to tackle indoor air contaminants at the root cause, including the AgriAir 1000 Surface and Air Cleaners combining the power of MERV and Carbon filtration with Photo Hydro Ionization (PHI). With a dedicated team of experts at the helm, Omni CleanAir leverages a comprehensive approach that encompasses air quality testing, filtration systems, and tailored consultation services to address the unique needs of each client. Lenora Rose (Channel Sales Manager), Jason Wilbur (President), and Jeff Abramson (Vice-President, Product) worked closely with the team on the selection, evaluation, and deployment of the AA1000 machines. Jeff Abramson can be contacted via email at Jeff.abramson@omnicleanair.com .

Brandon Schmitzer is the Chief Operations Officer and Head Grower for High Mountain Cannabis Company in Vassar, MI. He is also the Chief Consultant for Hydroponic Research (https://hydroponic-research.com/), where he serves as a consultant for other growers throughout the United States and Canada. Brandon can be contacted via email at Brandon@HighMountainCC.com .

ChemHistory – Alex Hoggan – Owner/General Manager (ChemHistory.com) ChemHistory is one of the largest and most respected Labs in Oregon. All of the samples were presented to the Lab in blind numbered samples with no reference to the strain or whether it was wet, dry, or cured. Alex Hoggan can be contacted at alex@chemhistory.com

Photos in sequence:

Our 2024 mother plants and clones in the new facility

Comments

One response to “Industry Perspective: 54 Green Acres Farm”

[…] Case study: 54 Green Acres obtained certifications for organically grown cannabis and focused on contaminant control to pass compliance testing for Aspergillus and improve air […]